jeepsr4ever

Charlene;131850 wroteHELP!! Getting ready to make our first cut but when I hit Reference Y, the Y axis traveled all the way to the right and off the rack and kept spinning until I pressed Stop. Then I hit Reference X and only the A stepper motor engaged... X & A are slaved... Very FRUSTRATED!!!

Why are you hitting ref? Why arent you hitting X home, Y home..ect?

Charlene

On the Arclight videos they show that you do that to square of the gantry and take the gantry back to table home...

jeepsr4ever

Your only allowed to listen to 40% of those videos. LOL

jeepsr4ever

For proper Ref you need a home switch on each axis and you need to go into your ports and pins and setup A home same as X which we are using for your maglok torch breakaway. My suggestion is learn to walk before you try to fly. Stay away from those buttons for now (ref)

Charlene

Alright, mistakenly thought that it was just part of the setup process. Now that my A motor traveled when my Z didn't, how can I make sure that they are square?

jeepsr4ever

Re-square by using one end of the rail. The most precise way is to use a laser on the edge of the 3/4" thick sideplates and measure off the gantry rail across.

wickedinhere

Did you figure out you motor problems?

Charlene

Okay. Thanks Matt.

Wicked - Not yet... my taxes are a bit more urgent right now. #-o Gotta give Uncle Sam his share! :banghead: I will go back out in the morning.

Charlene

jeepsr4ever;131853 wroteWhy are you hitting ref? Why arent you hitting X home, Y home..ect?

Do you mean the buttons that zero out the axis's? Also, does it matter that when I have zero-ed them out and move the gantry up the table the x axis shows positive numbers but the y axis shows negative numbers? Shouldn't they be both positive?...

jeepsr4ever

They are set to a co-ordinate system...just like your CAD. If you read the Mach 3 manual you can change the direction of Y simply by changing the "DIR low active" (It can be recheck or red X'ed in the ports and pins, motor outputs). You can change X as well but you better make sure the A axis has a different rotation direction (DIR low active) or you will bind. You can also change your keyboard keys that move your gantry by going to config/hotkeys and hitting the buton for the axis and then pressing a keyboard key. Before you do any of this consider that your zero in X and Y is not a home position it is only for cutting your plate and you will move in and out of the Y negative and positive direction. This movement is forced by how you import the drawing into Sheetcam and how its processed. Its simple once you got it but you may loose a few hairs trying to overthink it.

Charlene

Alright, the keyboard keys are set, the axis' are hooked up & running, we made adjustments to the torch plate (added bolts so that we could index it & not have to ziptie the torch because it is too heavy; added a channel in the top torch mount bracket for the gear rack on the machine torch),

[ATTACH=CONFIG]174[/ATTACH]

[ATTACH=CONFIG]175[/ATTACH]

[ATTACH=CONFIG]173[/ATTACH]

and tried our first cut!

[ATTACH=CONFIG]172[/ATTACH]

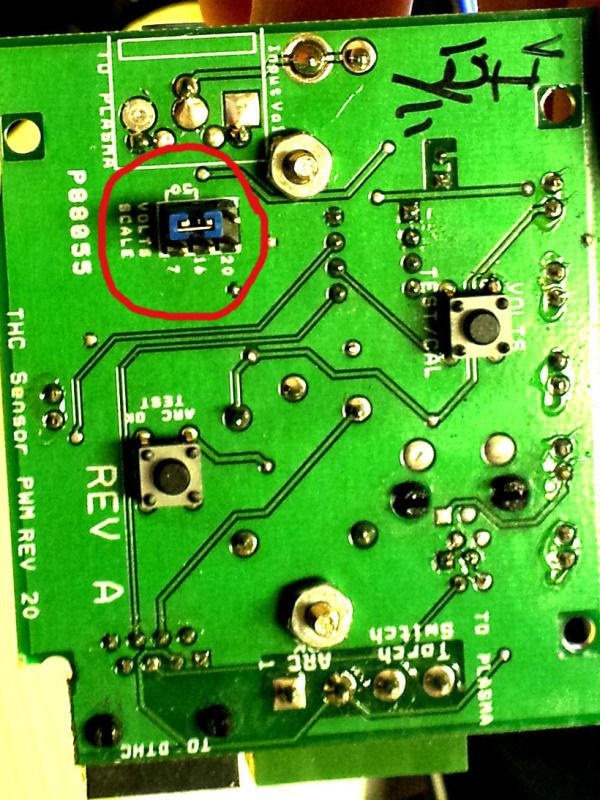

Had trouble with the cut due to the THC. Matt suggested a couple changes: first, change the pierce time for 5/8th; then, when that didn't work, he said to make some changes inside the DTHC box & in the candCNC box. This part was a little complicated. We needed to change tiny little switches so they match. This turned out to be not as simple as I had hoped. The DTHC box wasn't bad but the switches are not marked in the cnCNC box...

[ATTACH=CONFIG]176[/ATTACH]

Matt, I need your help with this part. The pins are not marked in the cnCNC box and the manual doesn't show that either. Can you just show me a diagram of how these should be configured for 50? The DTHC was set for 7. Thanks.

jeepsr4ever

They sure are on the bottom you will see a jumper plug and different numbers. It should be set for 50 so if you were set for 7 in the plasma set the plasma to 50 and you should be good to go as per the instructional.

Charlene

I will look again Matt. To be sure that I am looking at the right thing, are they the pins in the pic that I just added to my previous post? They look the same as the pins in the DTHC box but there are more pins?

jeepsr4ever

Charlene your looking in the wrong spot. The little black box is where the jumpers are for the THC. The smallish black box has 4 screws on the back, take the screws out and verify. If you set your CPC card to 50-1 your PWM box (little black box) should be set from the factory to 50-1. Also check here.

http://www.bulltear.com/forums/showthread.php?19199-Hypertherm-45-65-85-users-check-in-here-please

jeepsr4ever

Charlene it is possible that the factory did not set it to 50-1 here is the pinout on the bottom of a PWM box

Charlene

Thanks Matt, I probably wasn't clear. I had already already found the pins in the black box but I had thought that the other place I needed to check was in the candCNC box. I now understand that it is in the Hypertherm. I will fix that today! Thanks.

Charlene

Alright, here are the latest questions/problem:

1. When I load the g-code in Mach, after running the post processor in Sheetcam, it only loads part of the path. It doesn't seem to matter how many layers there are... What might I be missing?

2. Where is a good place for me to find all of the possible settings for my Hypertherm 85 for different metal thicknesses? I know that the manual has them but it doesn't seem to give me all of the settings that I need to enter in Sheetcam/Mach... especially the amp settings that I have to set on the Hypertherm.

3. Lastly, how do I know when to use the different consumables?

I hope that these questions are not so easy that I should have figured them out myself! :hairhair8:

wickedinhere

THe book should have the amp settings in it mine does but i have the pm45. Did you click operation and select which layer in sheetcam before clicking post processor? i assume you set up a plasma tool for cutting.

Charlene

I guess I am just overthinking the amps. Maybe once I have cut a bunch, I will stop second-guessing everything...! Yes, I have selected the layer(s) before the post processor & I did set up the plasma tool (I assume it is correct...)...

jeepsr4ever

If your only loading PART of your program into Mach 3 you most likely didnt load your sheetcam liscense or your mach 3 liscense in.