no, i wasn't using the rotary post processor. am now

but when i do it swaps the axis's. i did a tube cutoff and instead it slit the tube lengthwise.

i rotated the dxf in sheetcam -90* and it cut semi correctly.

the dxf line is 7.96'' long, which is the same as the circumference of the 2.54 tube

but the straight line cut lacks 5/8'' of cutting the tube. is this more motor tuning issues?

back on the axis swap issue with x and a axis and not rotating enough.

i cut a circle out of 2.5'' tubing and it cut as an oval, not enough rotation again

also the cut should have started on the left of this picture instead it started at the top where the torch is.

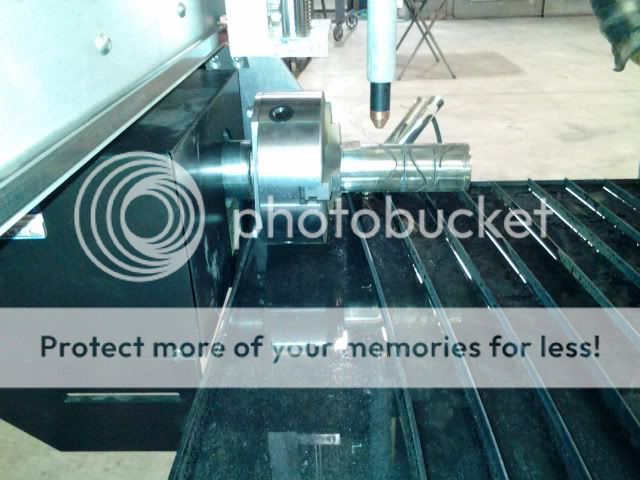

notice my ground strap. 1/2'' copper tubing hammered flat and clamped to the side of the water table with the ground clamp.

also want your opinion on the chuck location; should it be over the water like this

water splash is already rusting the chuck and makes that end of the table of limited use.

the dthc needs some tweaking too.

for some reason the torch is diving and hanging on the rotating tube and x axis movement.

the cuts above were done with the dthc off, with the dthc on the hole is G shaped

will call you in the morning, just wanted to post these pictures so we could discuss them tomorrow