First of all welcome to the wonderfull world of CNC plasma cutting. This is a great tool for making any shape 2 dimensional out of steel in seconds. This is a crash course which will help you go from 0 to 100 and get you cutting right away. :t:

First we are going to assume you have made a drawing and your going to save this drawing as a .DXF file like the one in this pic.

A good tip is to start a new folder for .dxf files. Some will do this for each thickness of material

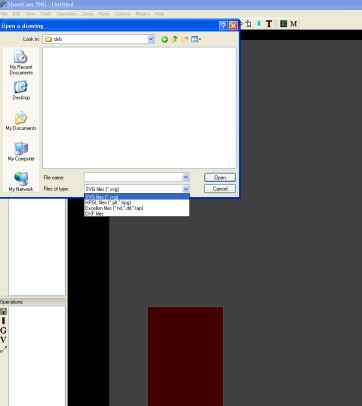

Next we want to open Sheetcam. We are going to assume here that you have the right post processor for your machine in the setup wizard (use MP1000 ). Open your drawing by using the "import new drawing" button under the "file" tab at the top of them menu. Make sure to switch your file type from .SVG to .DXF in the bottom of the pop up window so you can find your .DXF file.

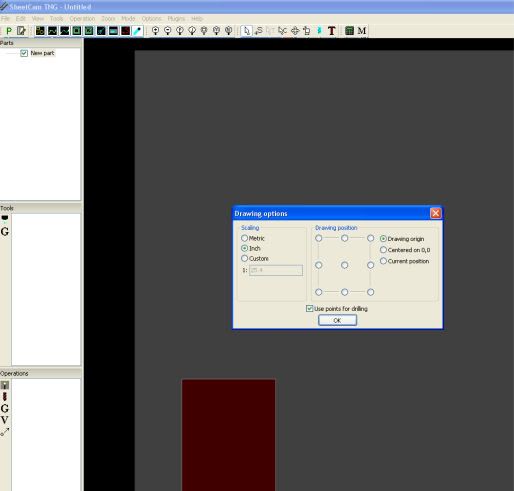

Located and open your .DXF file and run through the quick menu. It will ask you if you want inch or metric or where you want the .dxf to be used and if you want point for drilling. Points for drilling will command the plasma cutter to pierce only wherever you have a point in your .dxf drawing. This is VERY helpfull when you need an accurate hole that needs to be drilled or punched. It will in essence give you a pilot hole.

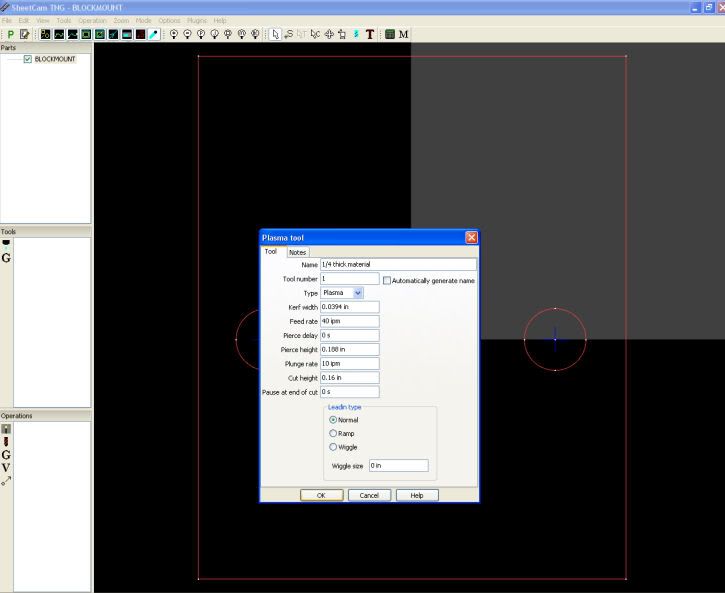

Now we select the little black and blue tool looking icon in the tools area in the middle left hand portion of the screen. This will setup your tool for Z axis movements. For this we are going to rename the tool "1/4" thick material". Note the changes in feed, pause, pierce delay..ect. These will and can be found in your plasma owners guide as well as multiple sources online. You will find a slight varation for each thickness of material and each amperage but the mfg suggested speeds and feeds will get you close.

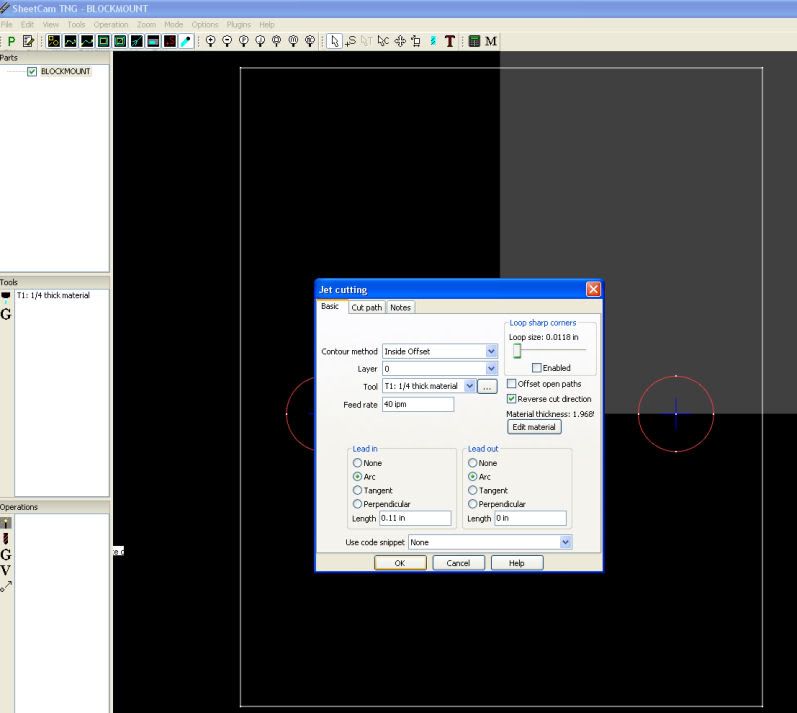

Next go to operations and click "Create a new Jet cutting operation". This will give you various options such as lead in and lead out..ect. For this example we will set it up with a arc lead in and out with a .110 radius. Lead ins and outs will greatly increase the quality of your finished part by minimizing gouging. We will also reverse direction which will get us moving counter clockwise which will give us the best quality cut. (most plasma cutters have a direction flow of air) You can change you cut path, optimise it manually and also put notes in. Now hit "ok" and the cut path will show up. Next we hit "P" or in the file menu we click the "run post processor". This will save as a .tap file which will be read in Mach 3.

Open Mach 3 using the Bladerunner or CNC plasma controller. Open the G code using "Load G code button" or in the file menu. Find your .tap file and click enter and it will come up on the screen. From here you find the edge of your material or wherever you set your X0 Y0 in sheetcam. Keep in mind THC delay must be set in Mach 3 settings and must be longer than the pierce delay you set in the tool you used in sheetcam to process the drawing. Tip volts takes over cut height so make sure your tip voltage is set correctly (typically 4-10 volts higher than your "cut profile" in Mach 3 depending on plasma cutter) You can zoom into the part in the Mach 3 screen using the right click mouse button and your scroll wheel. If your lost please rezero your X and Y to center your crosshairs on your part. You can jog your machine to the edges of the part on the screen to ensure you are going to be able to cut your part out of your material. Once your able to ensure you can cut your part out of the material by way of jogging you can hit start and cut your first part. Rmember you have to learn to walk before you learn to run. There now you have made your first part! :mrgreen: You will get faster at this and after just a couple times of running this you will be able to take a .dxf file and get it to running in under a minute. Good luck, have fun and stay safe!