rsbad454

Has anyone ever experienced a no compression issue with a rebuilt engine? I have a 304 bored to 310, rebuilt heads,, edelbrock performer intake, cloyes double roller timing chain installed straight up, comp cams 252 cam kit, holley ta 470...I cranked engine over repeatedly and no luck starting, didn't even sound like it wanted to. I thought dizzy was off 180, but made no difference. I notice by pulling #1 plug out to verify tdc I wouldn't get any pressure on my finger. I only noticed some suction on down stroke. I put compression tester on and read zero with throttle wide open.

I thought maybe comp pushrods could be too long, lifters are pumped up, cam timing off? I know I installed can dot to dot on chain sprockets with zero timing. Maybe. Sprockets were marked wrong....it's just very frustrating to sink all this time and money into something like this only to have a major issue. Any advice would be appreciated. Of all the engines I've built, never once had an issue like this.

jeepsr4ever

IF what you say is 100% accurate your timing set is off.

rsbad454

I was thinking that too and to pull the front of engine apart sucks, but I guess I need to go back to the beginning.

rsbad454

I suppose I should verify pushrods too...

tufcj

My bet is the pushrods are too long or too tight, holding the valves open. Even if the cam was off, you'd get some compression.

Bob

tufcj

rsbad454

tufcj;133280 wroteMy bet is the pushrods are too long or too tight, holding the valves open. Even if the cam was off, you'd get some compression.

Bob

tufcj

I totally agree....I don't get any attempt to start....I have spark and fuel just no compression. Only thing in common is the cam and pushrods. What else is odd these are non adjustable rockers, so it isn't like I adjusted too tight like on a Chevy.

rsbad454

Ok, I took a break from the Jeep for a bit, but decided to take another look at it. I pulled valve cover off and took rocker assembly off number one cylinder and used a remote starting button to bump engine around with my right middle finger over spark plug hole. I used my left hand to depress remote start button and two other fingers on left hand to feel pushrods as they cycled up and down with revolution of engine. My findings are when both pushrods are at the same level (should be at base circle) with number one piston at TDC and zero mark at TDC indicator on timing cover, I go to reinstall the rocker assembly, both valves are being opened slightly. I checked pushrods with stock units and they are the same length. Does anyone think the pedestals for rockers need to be shimmed?

tufcj

The base circle for the lobes on the cam you used may be larger than stock. You can put a shim under the bridge, but the ideal solution would be a shorter pushrod. Was the engine rebuilt, and the block decked or heads shaved? Both would also affect pushrod length.

Bob

tufcj

rsbad454

Yes, the engine was completely rebuilt....the bottom end was bored .030 with stock replacement pistons and the block was not decked. The heads were shaved only enough for a clean up. This is just an odd case scenario that I've never encountered before. I agree, I either need shorter pushrods or to shim the pedestals. I guess I can check and see if I didn't accidently get solid lifters instead of hydraulics. I did find these incase I need them.

http://www.jegs.com/p/Crane-Cams/Crane-Cams-Rocker-Arm-Bridge-Shim-Kits/1659559/10002/-1?Ntx=mode+matchall&Nty=0&Ntk=Parent&Ns=P_Margin%7C0%7C%7CP_Auxdesc1%7C0%7C%7CP_SKU%7C0&Ne=1%2B2%2B3%2B13%2B1147708%2B3&N=1143203&Ntt=1659559

rsbad454

rsbad454

Well, I have some more time to mess around with the 304, I'll see what I come up with. If I don't see anything obvious I'm going to pick up a 360 a fellow worker has laying around that runs.

rsbad454

Has anyone experienced broken rocker pedestals? I've found quite a few that were broken after they were torqued down and engine was rotated around. Maybe the pushrods are too long in this application?

tufcj

Several possible reasons. Pushrods could be too long, causing the slot in the rocker to hit the base of the pedestal. Too long a pushrod could also cause the valve to hit the top of the piston, the weak link is the rocker bolt. Check that you have the cam timed right, if your cam timing (at the timing gear) is off, the valves could hit the pistons.

What cam and pistons are you using? Have you had the block decked or heads resurfaced? Are you using 360 heads? The valve could be hitting the piston wall if you are.

I ran 0 deck flat top pistons with a .488 lift cam in a 304, and had to have the pistons fly cut because of clearance issues. I always test assemble and clay check EVERY engine I build for valve/piston clearance before final assembly.

Bob

tufcj

rsbad454

The 304 is bored .030 over with stock pistons. I'm using a comp cams 252 torque cam with a cloyes double roller timing set. Heads ( stock 304 ) were surfaced along with new valve guides, valves, seats and springs that came in the 252 cam kit. I have rotated engine around a million times to watch TDC of number one piston and rocker movement in association with damper marks, it appears to be on the money. That is the only thing I came up with, pushrod maybe too long for this application now. Coil bind I think would happen before piston interference in this case.

rsbad454

I ordered an adjustable pushrod, I'll see if my pushrod length is off.

rsbad454

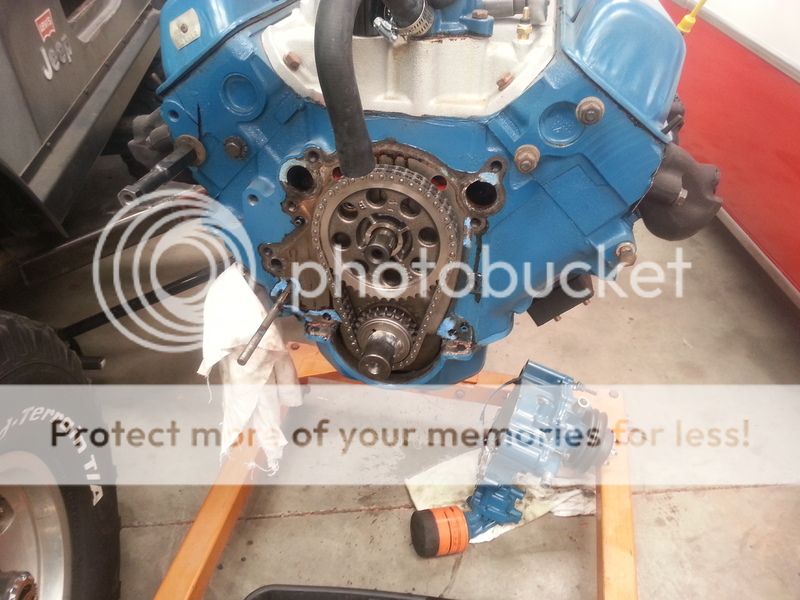

I finally got around to pulling engine out and found that I must have been on crack when I put timing set on. It is a cloyes 3 key lower sprocket that I aligned on the wrong key. I lined dot to dot upper and lower sprocket, bottom key was set for advance or retarded.

rsbad454

jeepsr4ever;133276 wroteIF what you say is 100% accurate your timing set is off.

I agree fully.... 🙂