Been a pain all year Mudrat...it's not so much the aftermarket systems, it’s just not having a garage to work in. Have to drag everything out of the house or storage shed to work on the truck. Then put everything back away before I go to work. Then it's been raining every day I have off...even rains for a week when I take off work!! It's been on jack stands forever it seems. I do lay on a piece of carpet that makes it alittle better. lol

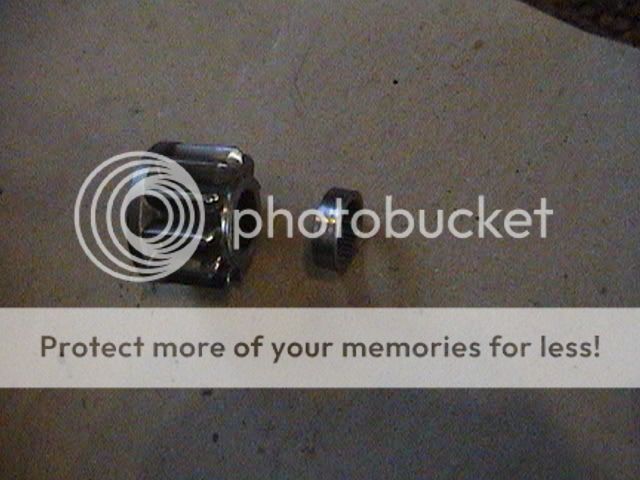

To fix the starter I had to cut the end off so I chucked the starter pinion gear into the drill with a wooden dowel and used a Dremel to cut the top off.

Leaves two pieces. The ring thats left gets ground down so it goes into the back of the pinion gear to act as a spacer for the amount cut off. The guy that sold me the starter said I could grind the end off and use a longer spring out of a stock Ford type starter also. But I liked this idea better.

Back on and sticking out further...giving good engagement depth :? Finally.

Yes Fuzz401 it's the swing pick up running dual lines into an Indy cover and pump. Sounds like you have run into problems also at sometime? I think next time one line would be enough...but 2 lines look cool. ha ha :mrgreen:

Got the mini back in and it works great! :!:

It's a tight fit in there with the oil lines and then I have the trans mission cooler lines running past also! (Got heat wrap for them someplace around here)

I also got the cross member for the np205 done and mounted. I used Energy Suspension universal bushing to make my own mount. When the engine comes out to get stroked after I get the garage up I'm going to make engine mounts out of the same thing. Maybe a set of 2" headers also...

Disk brakes plumbed on the 14 bolt done! Ugly but it’s a rush job. Need to finish some welding of leaf spring brackets yet and figure out a gas tank spot. (That’s the fuel line hanging over the rear end) Rear driveshaft is going to cost an arm and a leg so, thats the most I'll get done this year.

The Dana 60 front will have to wait until then also. That’s a spring over axle project. :smile: I've spent enough time under that truck lately 🙁: