After researching a little more, I found a good article, http://www.4x4wire.com/jeep/tech/shaft/diydriveshaft/ I measured at full droop and sitting level. I came up with about 1 3/4" difference in lentgh. I decided to center the slip yoke and make my cut. The new drive shaft was a bit thicker so I ground the yoke to fit. I''m picking up a dial indicator tonight and will mock everything up tonight. I don't feel like I have a safety issue as the yoke slides into the new tube like from the factory and is welded together.

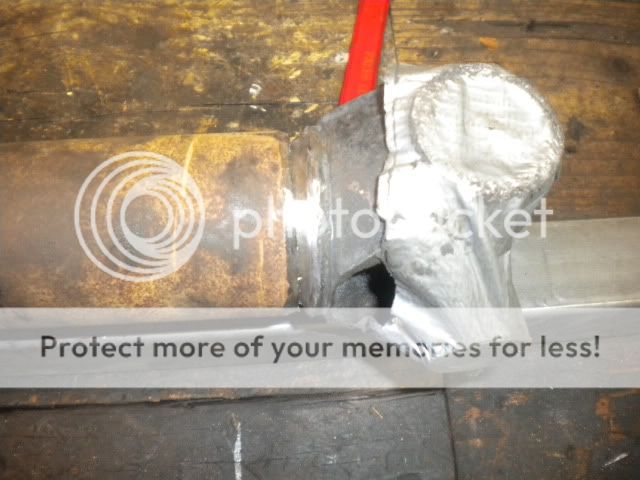

Here's my progress so far.

I'll take a few more pics when I true it up.