I'm guessing something is loose on your table. check your pinion setscrews, then check the Z head is tight on the vertical rail.

My build thread shows where to tighten. I'm gonna go with 100% fixed if you tighten the head. After running my table for months now, I had to dis-assemble the Z-head, clean the rail, and re-set the clearance to chase out that exact ripple.

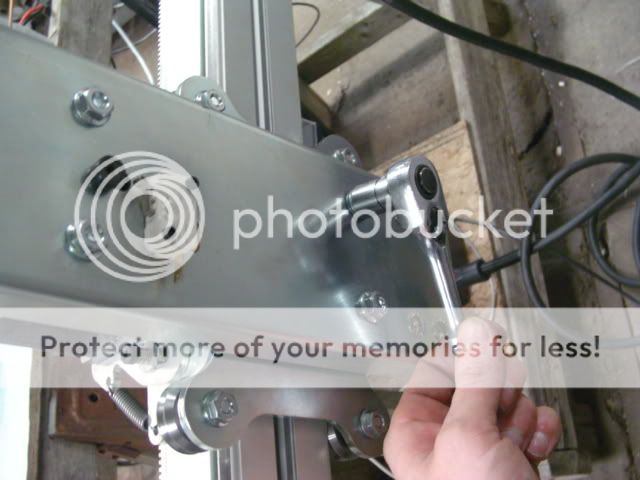

easiest way to check - lower the Z to the work. Wiggle the head. If it wiggles, fix it. the bearings are on cams, you just move 'em over till there is no play on the rail.

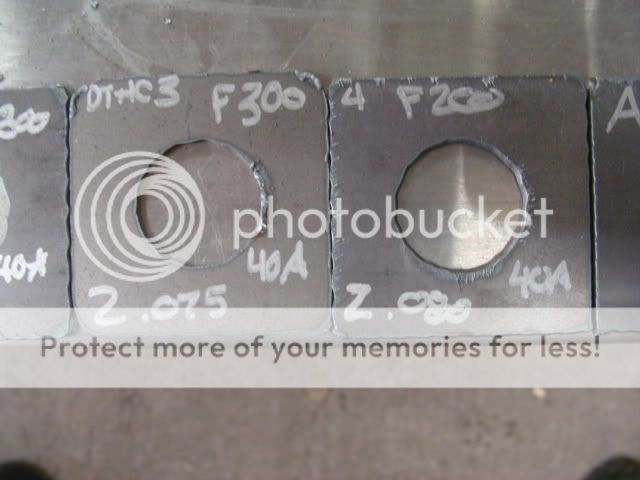

Here is my documentation on the same looking ripples you have -

something is moving/not rigid. looking at the toolholder.

hhmm, floating head on Z is shakey, needed to preload these two bottom bearings on the rail. the one on the left is adjustable on a cam to preload.

frigged with that a bit.

I'm after doing this twice in 6 months, once right at start-up, like you are seeign now, and once a few weeks ago after a bunch of use.

Hope this helps.