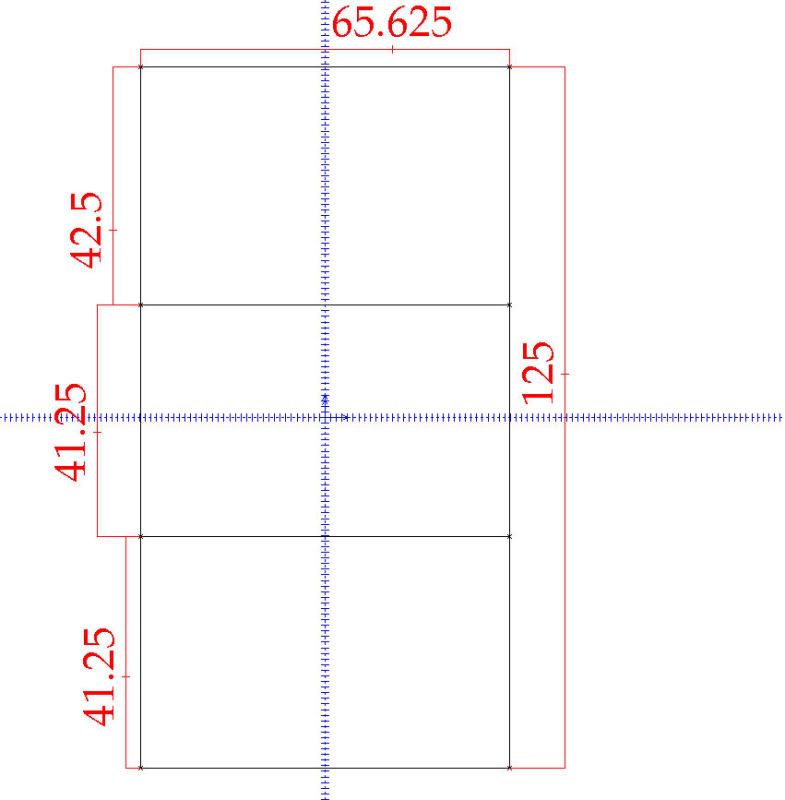

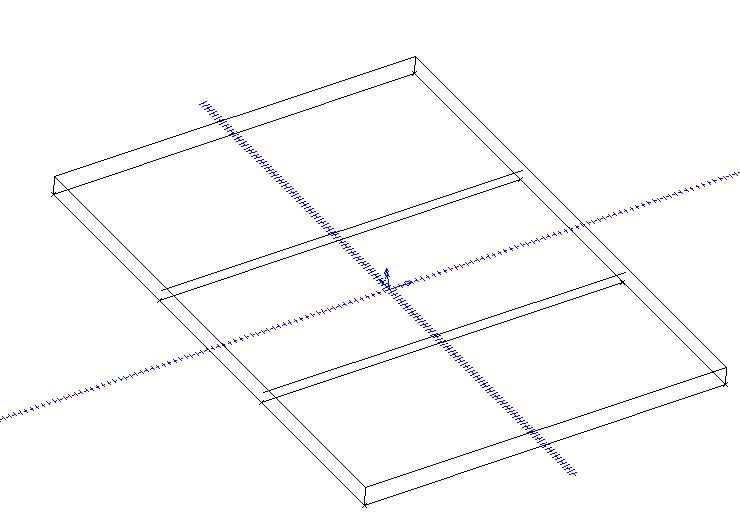

This is a build instruction for a 5x10 water table. This can also be modified to work with any size table.

Water pan is setup to use 3 pieces. The pan is 2.75" deep allowing us to use a 2.5" wide flat bar for slats and a .125 support stock on the bottom of the pan. The top pan segment has a 2.75" bend (brake) on the left, top and right side as you look at it in the drawing, the bottom of the top pan segment has a 1" bend which will allow it to be seam welded to the middle segment. The middle has a 2.75" bend on the left and right hand sides and a 1" bend on the top and bottom alowing it to be welded to the top and bottom segments of the water tray. The bottom piece has a 2.75" bend onthe left, bottom and right hand side and a 1" bend on the top side.

Lay your three pieces on your support table and seam weld them together. You may want to add some drains with a hole saw, a pieces of pipe and a pipe plug.

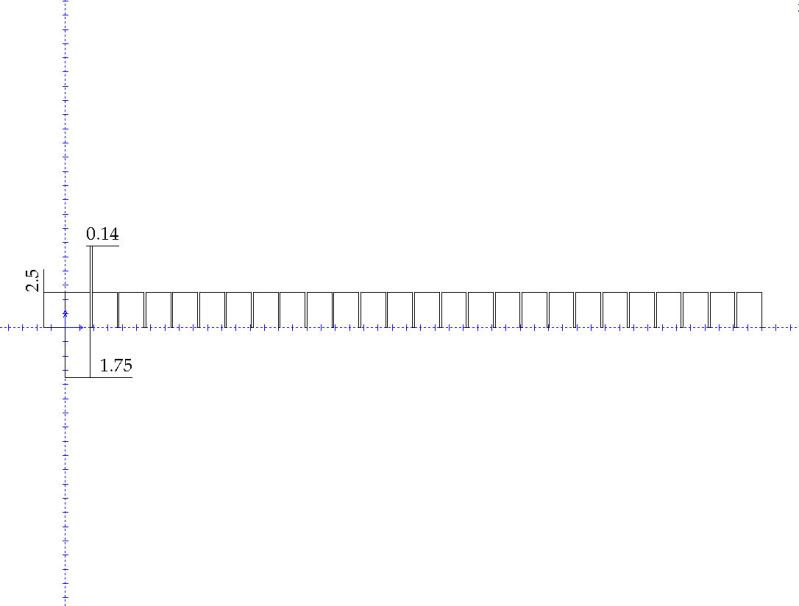

Slats and slat support

The slat support can be made one of two ways.

- With your plasma table assembled make a .dxf of a slat support like this to be cut out of 2.75"x2.75"x1/8" angle iron.

- The other way is to weld in 2.5" steel bars spaced apart using an existing 1/8" flat bar for slat material. (**we suggest a 1.75"-2.00" spacing for slats) Like this

Weld slat support into water tray and add a support in the middle of the tray the same thickness of the angle iron or if you welded side supports on the tray you dont need to have a center support.

***SLAT SUPPORT IS INSTALLED***

Slats

Slats are going to support your material for plasma cutting. these are a consumable part of your table and will be replaced from time to time depending on cut time and amperage. The goal with slats is to make them as cheap as possible without sacrificing support. For our slat design we will use long bars fo flat 1/8" thick stock that is 2.5"s wide and cut them to fit in our plasma table water tray.

Measure the width of your finished water tray and cut slats within 1/8" of the width. The reason we give this tolerance is to allow for and movement of the slat and for thermal expansion as well as ease of removal and replacement. Cut your slats and install them into your table. You are now ready to cut if you have followed the "Setting up your electronics" instruction on this forum.