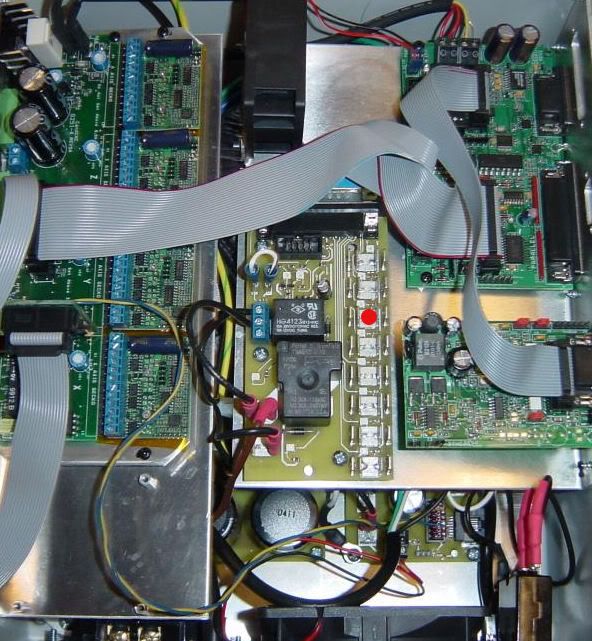

Those with the single controller box will use the terminal marked in red for the Z torch height control.

YOU MUST ACTIVATE Z AXIS HOME SWITCH IN MACH 3 FOR DTHC TO WORK. UNDER PORTS AND PIN IN THE CONFIG TAB. MAKE SURE Z HOME IS ACTIVATE AND TEST Z AXIS LIMIT SWITCH USING THE DIAGNOSTICS TAB IN MACH 3. IF Z HOME DOESNT LIGHT UP NOT WHICH LIMIT DOES LIGHT UP AND CHECK IT IN PORTS AND PINS AND SWITCH Z AXIS TO THAT LIMIT SWITCH (PORT AND PIN)[/b]