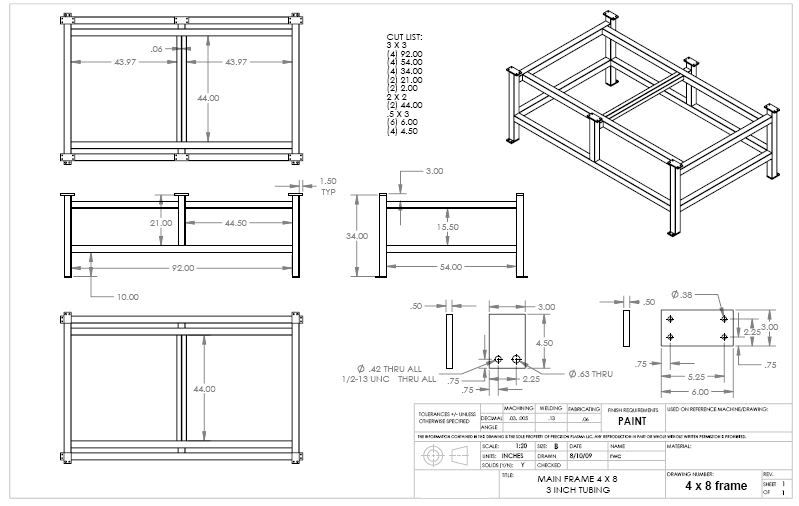

Plans are also available in Metric measurements as well. All plans come with a material cut list! :t:

The print shows exact heights and the table is engineered to work within these parameters. Should you be up to 1/2" off in height you will have adjustments on the torch bracket.

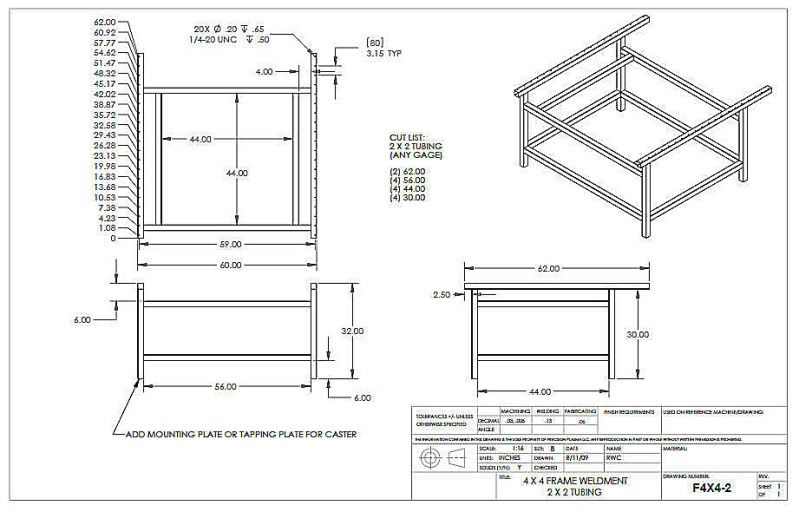

After drilling and tapping the top rail support you will want to install the rails. The X or Y long axis(depending on how you hook up the plugs) long axis should be bolted in using 3/4" 1/4-20 bolts with integrated washer heads. This allows you to drill the holes to 1/2-20 and leave .100" room for final adjustment. Put the gantry on the rails and note the wheel position on the "V" rail. Install the long axis motors without springs but with gears and move the gantry up and down the rails. If you run into an area where side to side adjustment is needed you can move the rail with the 1/4-20 bolts or you can move the drive wheels. If you end up with the gear rubbing the rack your table has a twist in it. This is a not to uncommon ordeal. You can shim the support rail to get the twist out of the table. When its moving smooth with a push you are done with this step.

Find the motor with the 20' cable attached (5' longer than others) and use that for the long axis 2nd drive on the other side of the gantry. You can send the wire through the gantry by using the holes in the side plates of the mounting brackets. You may have to take off the other side bracket and re-install the 4 retaining bolts after running the wire through it. X,Y,A axis motors use a set screw to attach drive gear. (Z axis gear uses loctite green or red) SEE Z AXIS DRIVE GEAR SETUP

The Z axis motor is setup with a smaller drive gear. This gear must first find the correct depth on the shaft of the Z axis motor to allow full engagement. Put the gear on the shaft and tighten Z axis motor to Z axis and look vertically down to see how the gears are meshing. (Note Z axis shaft will appear very close to gear rack) Once you get the gear in the right place marke the shaft and take the gear off. You will want to then use some green or red locktite (Blue is sufficient as well) and locktite the gear into place and install right away and check depth of gear. If the gear is inthe right position you are done and finish bolting Z axis motor to Z axis.

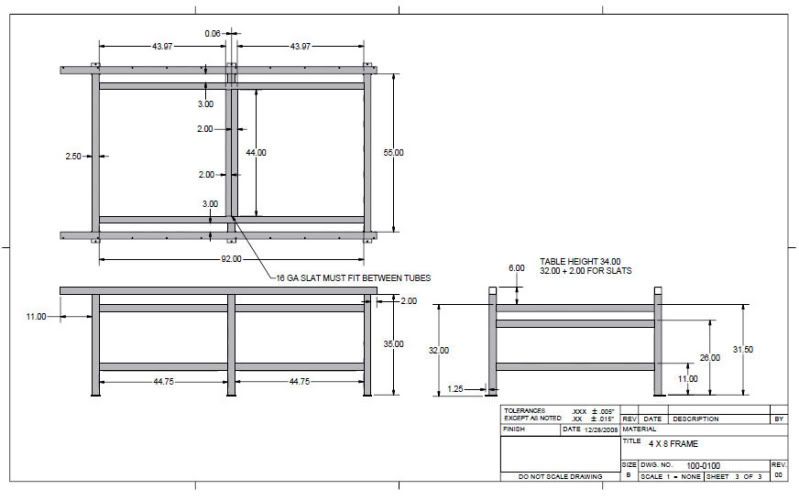

Your table should look similar to this when you have the gantry on and slats in.

[/img]

[/img]