USE THIS ONLY ON 2011 AND EARLIER MODELS

We have had a couple of inquiries as to how fast you can go from 0-100 with the system we offer. If you ordered a gantry kit or a complete table and are setting up software please follow these instructions.

- Setup Mach3 using the MPTHC1000 as the primary profile and not the general buttons (Mill, Plasma, Turn, EMD...ect)

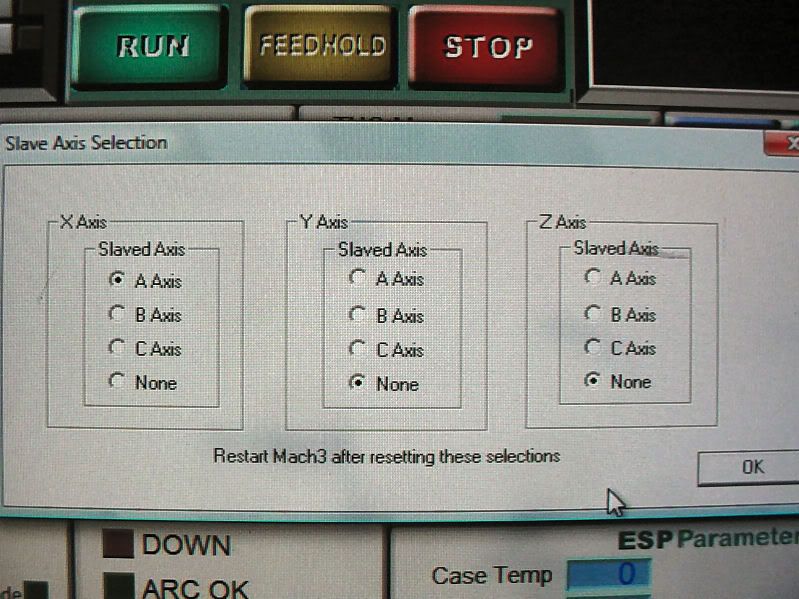

- Go into your Mach3 once you are running the DTHC1000 profile and go to your config tab. Because we use a dual drive zero backlash system you want to slave an axis. Some will slave X and A and some will slave Y and A depending on which cables are hooked up. For this example lets slave X and A. Remember to save you settings.

- Now lets go to config and motor tuning. Bulltear tables use a very smooth gear on all axis but not the same size gear or pitch on all axis. For X,Y,A axis the following is used.

1019.1 Steps

1000 Velocity (V can be 1-1000)

30 Accel (accel can be 1-50)

Z axis (torch up and down)

1273.9 Steps

150 Velocity

50 Accel

This gives you very accurate movements of .001" (2,754,000 points on a 4x4 table, actual travel 54x51 or 5,200,000 points on a 4x8 table, actual travel 104x50)

You will get a demo copy of Sheetcam you can use for many projects. To use Sheetcam you move the MPC1000-THC.post into the "post" directory in Sheetcam using your windows documents browser and click and drag or cut and paste.

You will need a drawing or CAD software for use with our tables. Their are hundreds to choose from and some are even free.

This completes the software and motor tuning area of your table. This will get you up and running with the software sent with the electronics provided you have some CAD software