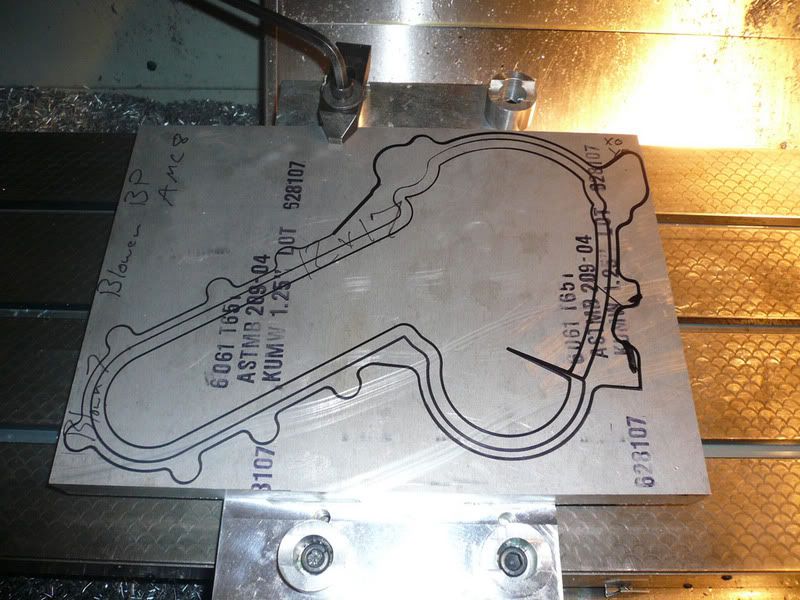

Here is the first block to be machined. It is approximately 12"s by 17"s and is 1.25" thick. A spendy piece of aluminum :idea: Chucked a sharpie into the spindle and let the machine draw the outline of the part of the aluminum. Piccasso :?: The inside line the the exact path of a 2 flute 3/4" endmill spinning at 5200rpm and 27 inches per minute.

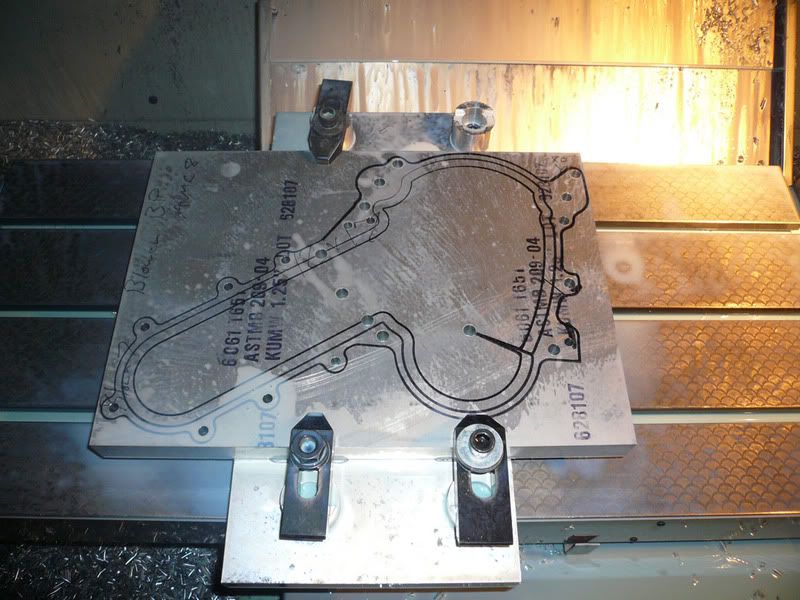

Time to pop some holes

Milling out the cavity for gear and chain clearance

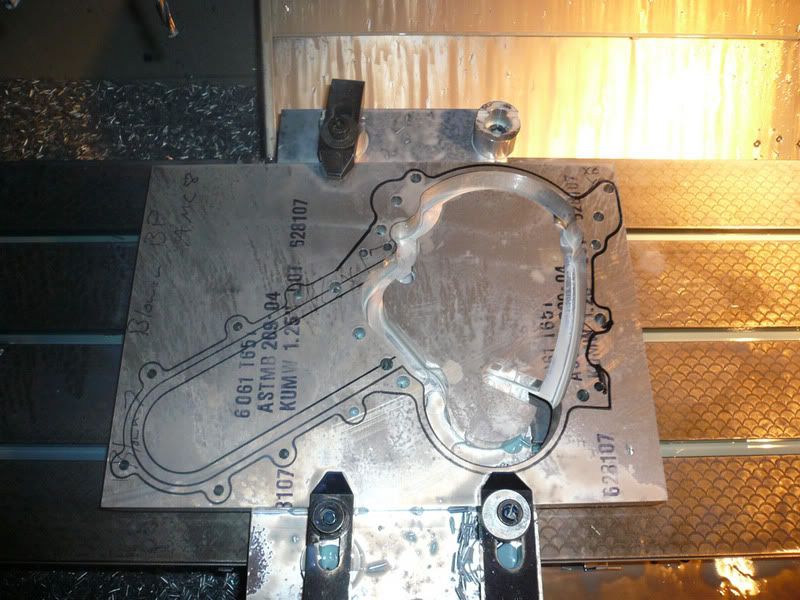

Roughing out the cavity for the dry sump chain

Cavity all clear

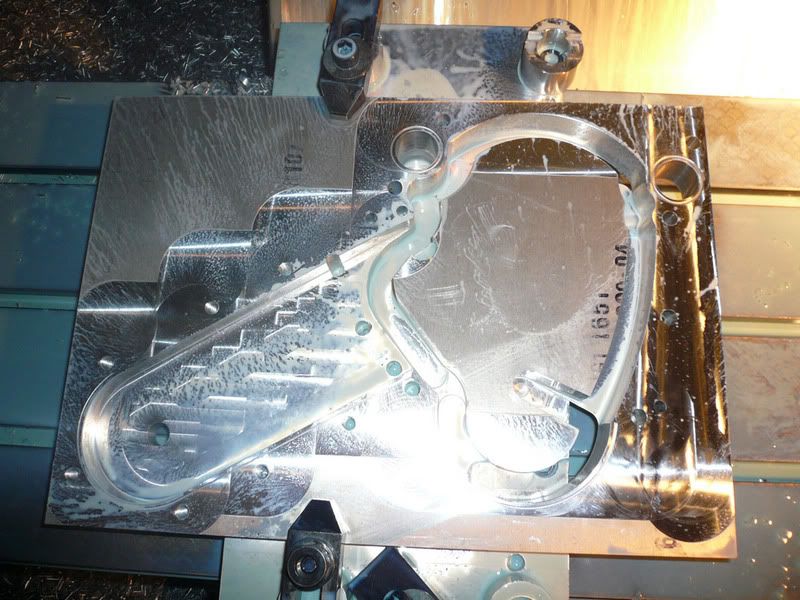

Milled down extra stock for a 1.2500 thickness and a flat surface.

Holes tapped and the precision dry sump hole reamed out

RE_FIXTURE..If you look closely you will see the oil control grooves for a no leak condition on a soft gasket. This is the finale staging for the profile on the base plate. From here is will get a counterbore in the back and be flipped over for oil pan seal and tapped holes for the two front pan bolts.

Thats all for now...I know its just a tease but the best I am saving for next.